PRODUCTS

SERIAL MANUFACTURING & CUSTOMISED SYSTEMS

AIR6 SYSTEMS | AIRBORNE ROBOTICS provide a full UAV product and equipment range to cover more than 95% of all currently possible applications. We strive to deliver only highest quality products, MADE IN EUROPE. Our systems can be mounted with multiple sensors (RGB, thermal, multispectral, LiDAR, etc) and are specifically designed to provide meaningful data. While our core business is designing & manufacturing drones, we provide our customers with end-to-end TURNKEY UAV SOLUTIONS for each application – comprising of UAV hardware, integrated sensors, customisations, operating and flight planning software, post-processing software and support & training.

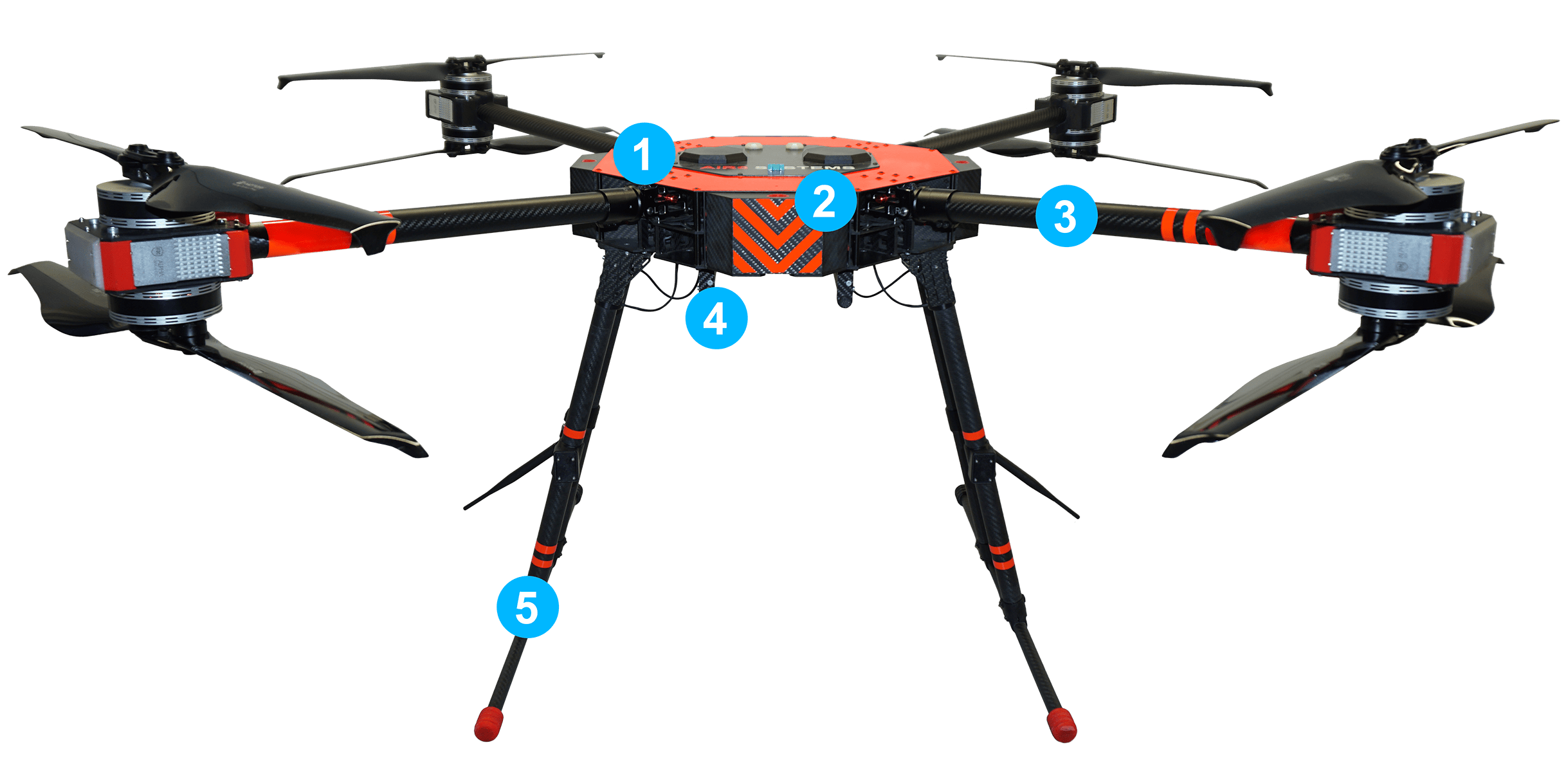

AIR8 MEDIUM LIFTER

The AIR8 drone is designed for medium payload and medium flight range missions. It is equipped with enough power reserves for Laser scanning / LiDAR surveys, customised sensors (eg. radiometric, muon) and for heavier film camera equipment. Our AIR8 possess the market-leading flight characteristics (flight time, payload capacity, redundancy and water resistance).

Recommended payload:

Up to 10 kg

4x Li-ION batteries with

extended charging cycles

(up to 1,000x)

Flight time:

Up to 60 minutes

Temperatures:

-20°c to +60°c

Newest flight technology. Enhanced battery performance.

- OctoCopter (4 arms / 8 rotors)

- >90% carbon

- Foldable / detachable arms

- Retractable landing gear

- Small pack size delivered with hard case

- Weather resistance: IP54 (dust and splash water safe)

Optional:

- Full redundancy package

- Real Time Kinematic (RTK), Post Processed Kinematic (PPK), Precise Point Positioning (PPP)

- 4G, 5G or satcom communication module

- Logistics functions: payload transport and drop-off

MODULAR CONSTRUCTION

4 Component Groups

![]() Centre body

Centre body

![]() Li-ION power batteries

Li-ION power batteries

![]() Detachable & collapsible arms

Detachable & collapsible arms

![]() Mounting rail for multiple payloads

Mounting rail for multiple payloads

![]() Detachable landing gear

Detachable landing gear

Eight highly efficient carbon rotors

Water resistant: no cables exposed

Wind speeds up to 60km per hour

Flight height 4,000m ASL

Multiple sensors and payloads

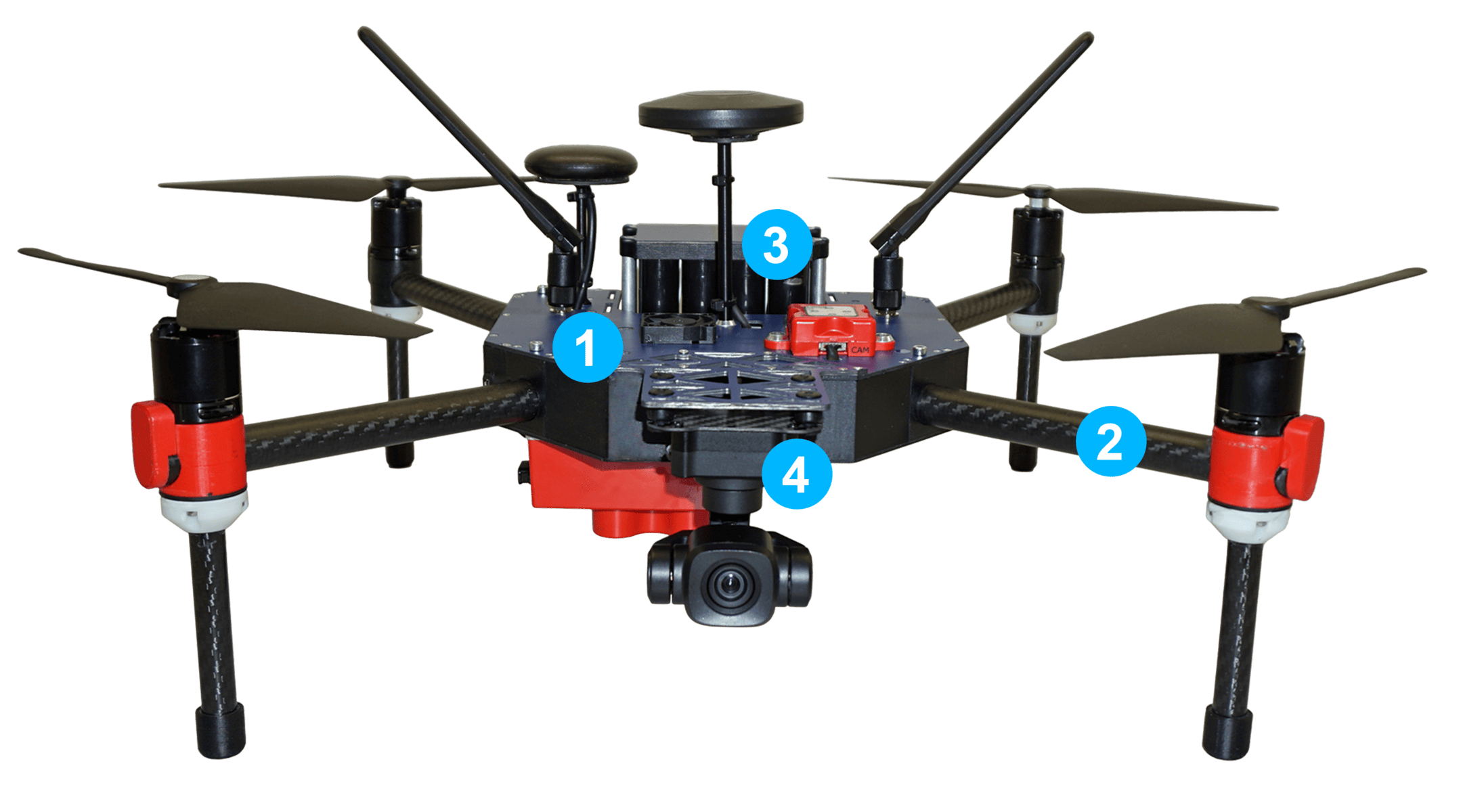

AIR4 RUGGED

The AIR4 Rugged is a powerful but compact system that combines the latest advanced UAS technology features for EXTREME working environments and UNIVERSAL applications. Inspired by ruggedized hardware this AIR4 is a durable and robust drone that has a payload capacity of (>3.5kg). It’s light weight body and versatile construct allow for multiple sensors and customisations. With superior powers reserves it can handle extreme wind and weather conditions.

Recommended payload:

<1.5 kg | possible: <3.5kg

2x Li-ION batteries with

extended charging cycles

(up to 1,000x)

Flight time:

Up to 60 minutes

Temperatures:

-20°c to +60°c

Versatile and agile in extreme conditions.

- QuadCopter (4 arms / 4 rotors)

- >90% carbon

- Detachable arms and landing gear

- Small pack size delivered with hard case

Optional:

- GPS-denied navigation and DAA (Detect & Avoid)

- 4G / 5G communication modules

MODULAR CONSTRUCTION

4 Component Groups

![]() Centre body

Centre body

![]() Detachable arms

Detachable arms

![]() Li-ION power batteries

Li-ION power batteries

![]() Detachable landing gear

Detachable landing gear

![]() Mounting rail for multiple payloads

Mounting rail for multiple payloads

Multi-rotor copter with 4 motors

Extreme weather capabilities

Wind speeds up to 60km per hour

Flight height 4,000m ASL

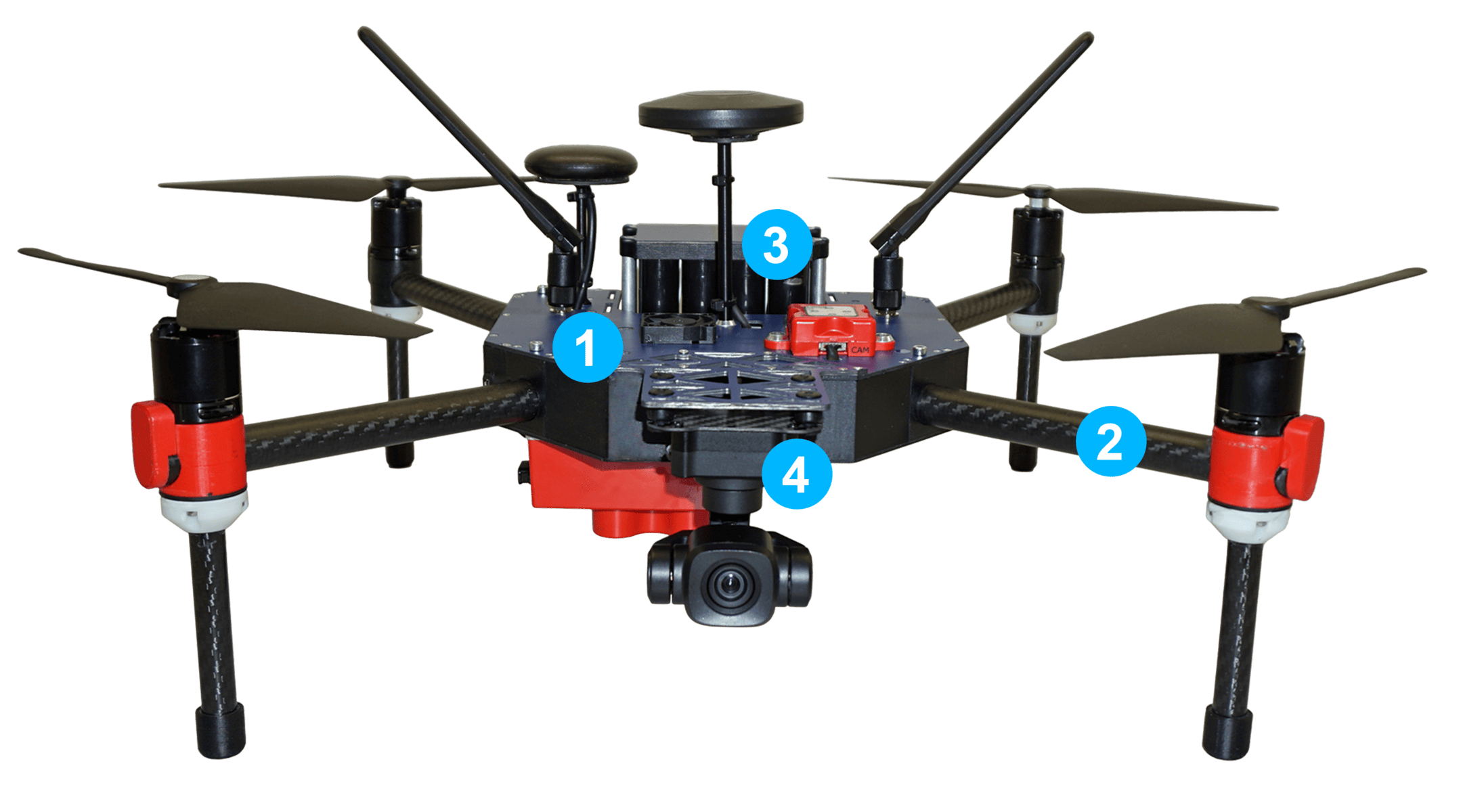

AIR4 LIGHT

The AIR4 LIGHT is a light-weight (<2.5g) drone which is very versatile and structured with open-platform architecture. Due to its optimal price / performance ratio is the perfect R&D drone. I can be equipped with a range of light payload sensors (RGB, thermal, multispectral) for data collection or with our complete array of systems sensors for GPS-denied operations. It can operate individually or in a swarm formation with AIR4 LIGHTs or our other drones. It is also popular as a secondary, practise drone in combination with our larger systems.

Recommended payload:

Up to 0.5 kg

1x Li-ION batteries with

extended charging cycles

(up to 1,000x)

Flight time:

Up to 40 minutes

Temperatures:

-20°c to +60°c

Light-weight drone with great price-performance-ratio.

- QuadCopter (4 arms / 4 rotors)

- >90% carbon

- Array of sensors

- Detachable arms and landing gear

- Small pack size delivered with hard case

Optional:

- GPS-denied navigation and DAA (Detect & Avoid)

MODULAR CONSTRUCTION

3 Component Groups

![]() Centre body

Centre body

![]() Detachable arms

Detachable arms

![]() Li-ION power battery

Li-ION power battery

![]() Mounting for multiple payloads

Mounting for multiple payloads

Position Camera

Companion PC

2D LiDAR

AIR4 NANO

The AIR4 NANO is an ultra-light (<250g) drone for surveillance and tactical reconnaissance. It can be equipped with a range of light sensors (RGB, thermal, distraction) and can operate individually or in a swarm with other AIR4 NANOs or our larger drones. It can serve as the eye-in-the-sky while companion drones are performing other functions.

Recommended payload:

Up to 100 g

1x Li-ION batteries with

extended charging cycles

(up to 1,000x)

Flight time:

Up to 30 minutes

Temperatures:

-20°c to +60°c

Ultra-light weight reconnaissance drone.

- QuadCopter (4 arms / 4 rotors)

- >90% carbon

- Detachable arms

- Small pack size delivered with hard case

Optional:

- 4 different payload modules

MODULAR PAYLOAD OPTIONS

4 Payload Modules (upward and / or downward facing)

![]() RGB / daytime camera

RGB / daytime camera

![]() EO / IR, thermal camera

EO / IR, thermal camera

![]() Combined RGB & thermal camera

Combined RGB & thermal camera

![]() Distraction payload

Distraction payload

Multi-rotor copter with 4 motors

Li-ION power battery